Sheet metal fabrication is a process whereby flat metal sheets are turned into metal products and structures. Sheet metal fabrication methods involve the transformation of different types of sheet metals into components and parts. Therefore, this metal-forming process is not just a single manufacturing process but, instead, a collection of forming techniques. These techniques work in conjunction to help produce specific parts. Read More…

Maysteel provides complex sheet metal fabrication with a focus on design for manufacturing. Founded in 1936, we combine our extensive engineering experience and market knowledge with an expanding supply chain footprint, allowing us to fabricate products that others can’t. We design, engineer and manufacture custom OEM sheet metal enclosures, kiosks, cabinets and racks. We have locations in the...

At Continental Industries, we specialize in delivering top-tier sheet metal fabrication solutions, catering to a diverse range of industries with our commitment to excellence and precision. With decades of collective experience and a robust infrastructure, we have established ourselves as a trusted leader in the sheet metal fabrication sector. Our product portfolio includes a wide array of sheet...

Accurate Metal Fabricating has been providing metal fabrication to OEM's and job shops for over 80 years. We fabricate, engineer, and perforate to the most precise specifications for the most demanding companies. We offer a full range of metal customization and fabrication capabilities that bring your design to reality. Our abilities range from forming and laser-cutting to powder coating and...

At Precision Metal Works LLC, we pride ourselves on being a leading provider of top-quality sheet metal fabrication solutions, dedicated to delivering precision-engineered products and exceptional services to our valued clients across various industries. With years of collective experience and a passion for innovation, we have established ourselves as a trusted partner in the field of sheet metal ...

Since 1981, American Industrial has been on the cutting edge of all things sheet metal. This has helped us achieve our spot as a leader of the industry.

More Sheet Metal Fabricating Companies

The basic techniques used in sheet metal fabrication include bending, stamping, cutting, punching, welding and finishing. The sheet metal components are made from a variety of materials including steel, stainless steel, brass, copper, and aluminum.

Types of Sheet Metal Fabrication Processes

The different types of sheet metal fabrication processes include:

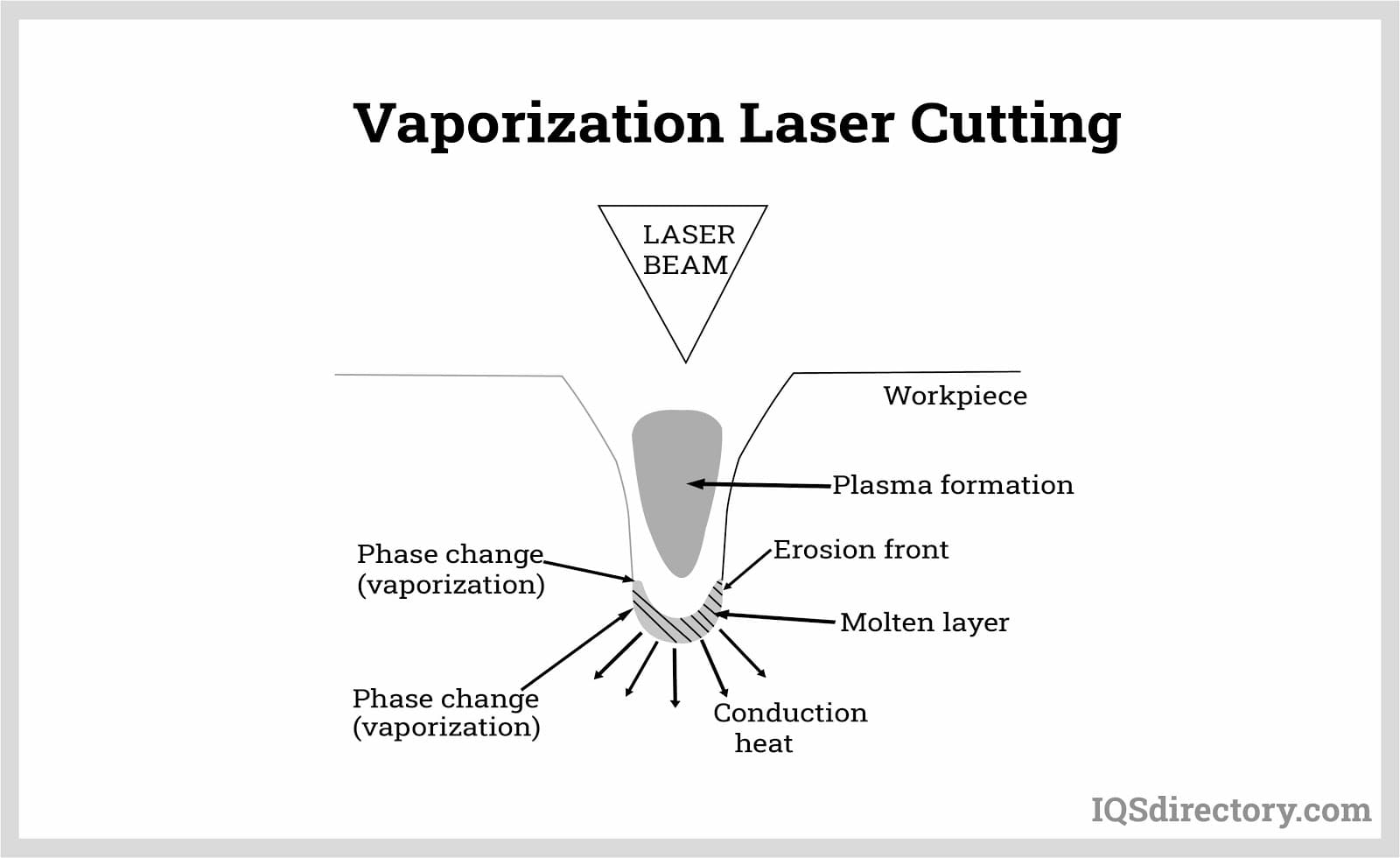

Cutting

This is the first step in the manufacturing of sheet metal. This process involves cutting the metal sheet. Manufacturers begin with rectangular metal sheets and, depending on the part design required by the customer, the material is cut to size. The cutting of sheet metals can be performed using a variety of tools like snips or shears to cut through the metal.

Stamping

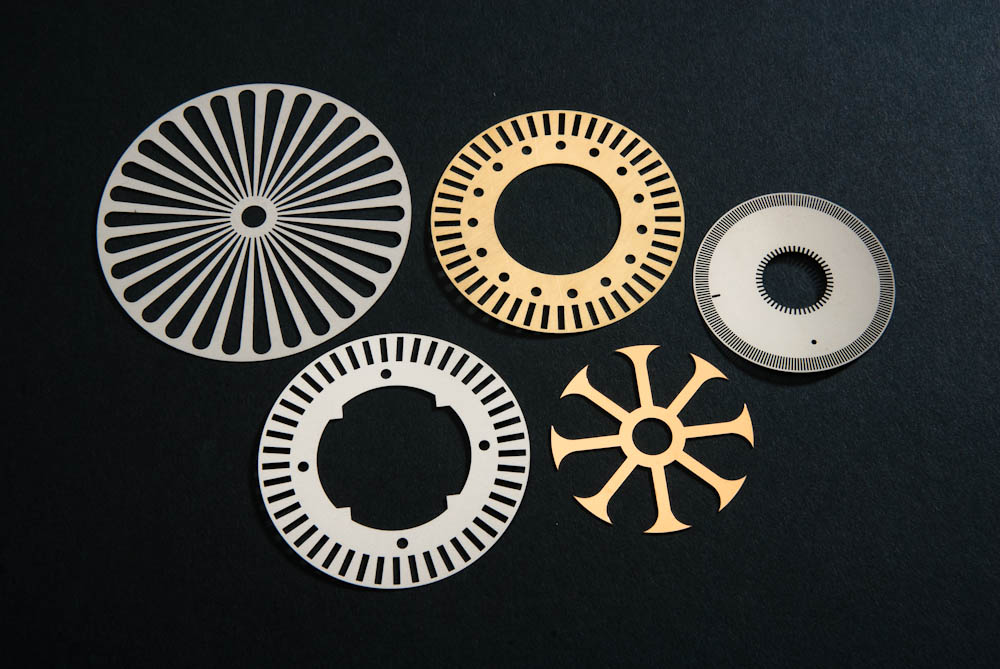

This type of process is a cold-forming method that is responsible for transforming flat metal blanks into different shapes. This process incorporates the use of a tool and a die which, when impacted, transforms the metal form through the use of shear pressure. Stamping encompasses bending, punching, and embossing and It is also involved with flanging, which is responsible for forming flanges.

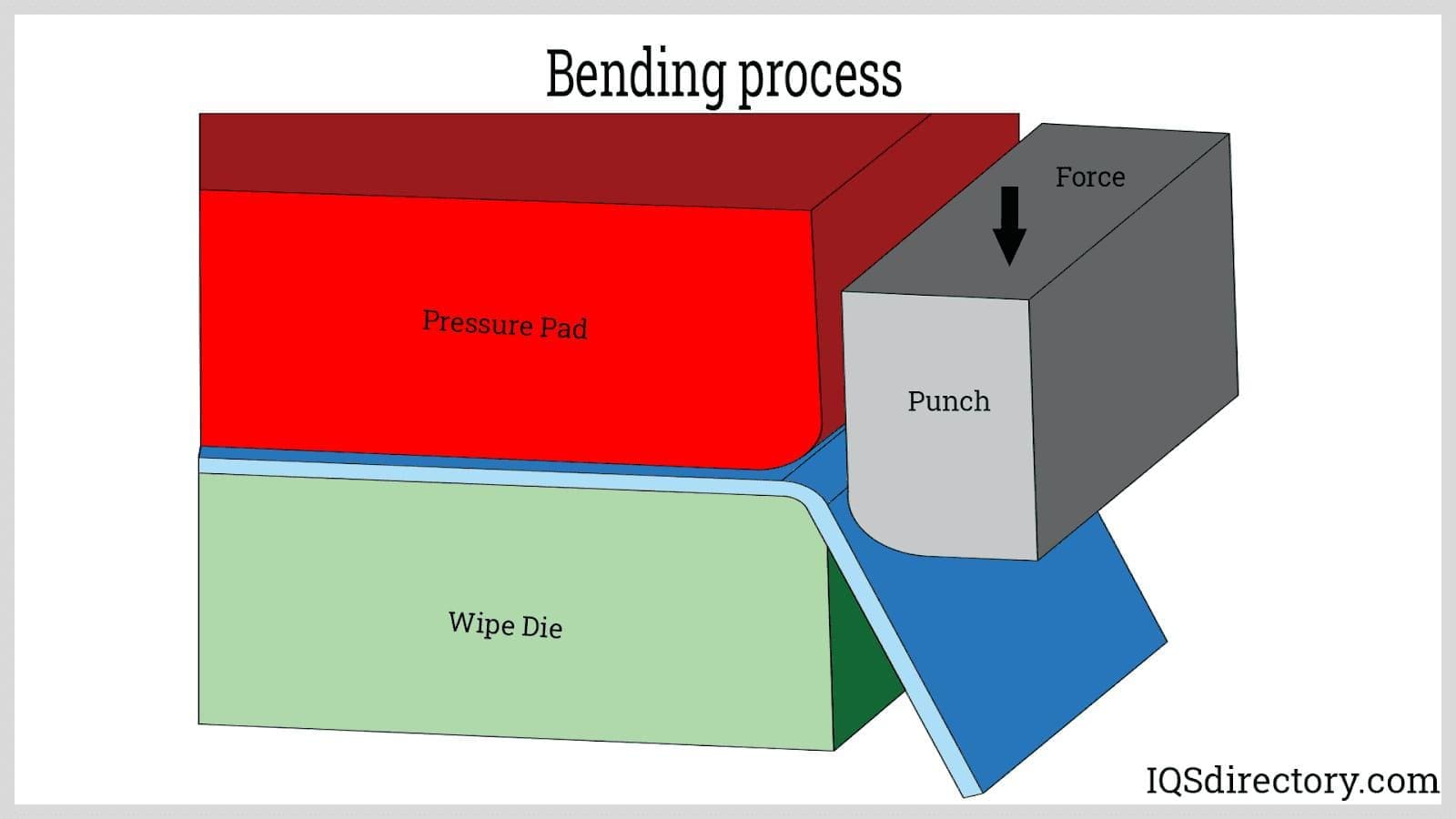

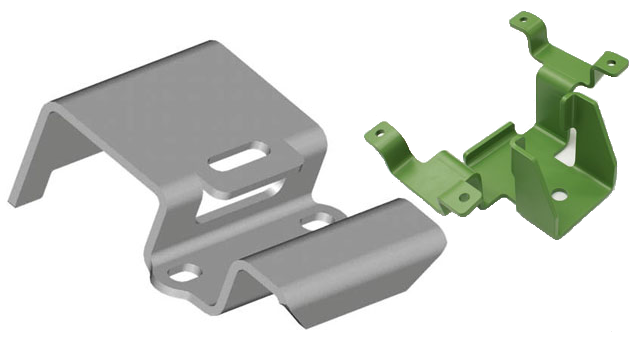

Bending

This is a critical stage in the fabrication of sheet metal. This stage includes the bending of metal sheets. Most metal fabricators use rolling machines, press brakes, and other equipment for carrying out sheet metal bending. The equipment used is capable of creating standard shapes like U-bends or V-bends.

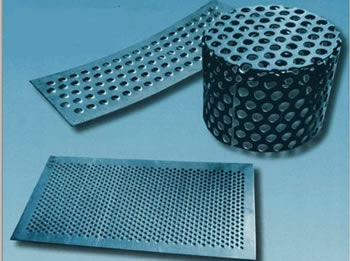

Punching

This technique is utilized for creating holes in metal sheets. This method depends on a punch as well as a die. These items make use of shear force for perforating holes into the metal sheet. The die serves to collect the scrap material that is created from the hole.

Welding

This is one of the final stages in the fabrication of sheet metals. It is a fundamental process for the joining of sheet metal pieces together to form a single part. There are many different types of welding techniques used including MIG, TIG, and stick welding.

Applications of Sheet Metal Fabrication

- Sheet metal fabrication can be applied in many areas including the electronics industry. It is used in factories for making cell phones, computers, drones, tablets, automated machinery, telecommunications equipment, etc.

- Sheet metal fabrication is utilized in chassis construction.

- It is used for making enclosures as well as housings. When there is a requirement of making a protective shell to enclose an electronic mechanism, sheet metal fabrication comes into play.

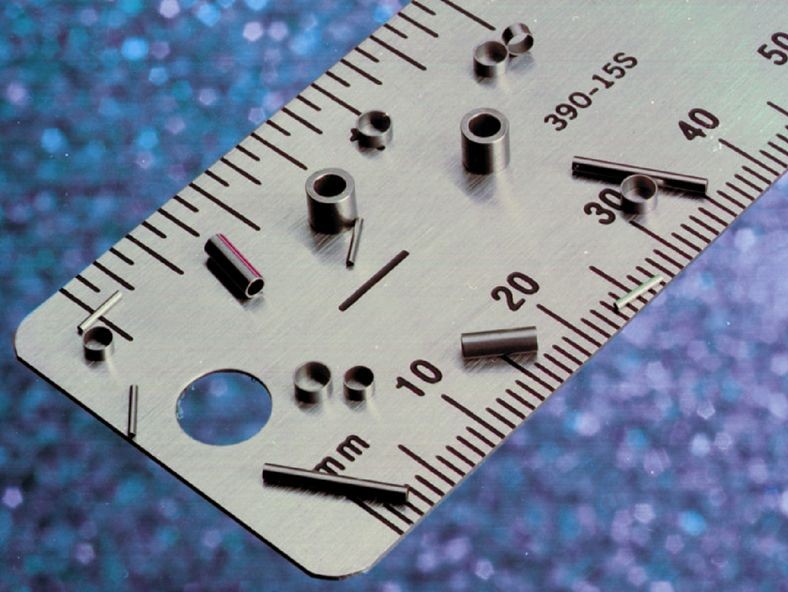

- Sheet metal fabrication is utilized for making brackets and small components. Cable connectors are an example of these small components

Benefits of Sheet Metal Fabrication

The benefits of sheet metal fabrication include:

High Precision Parts

There are many different techniques of sheet metal fabrication like bending, cutting, stamping, shearing, blanking, laser cutting, etc. All these processes are now made possible through the use of automated machinery that is capable of creating high-precision parts, as well as various designs at specific tolerances as required by the user. High-precision parts are a requirement in the automotive, construction, healthcare, and aviation fields, as well as in various food and beverage applications.

Custom-Built Design

Sheet metal fabrication allows for the creation of custom-built parts as well as components. If there is a product concept that needs to be transformed into reality, sheet metal fabrication can produce workable prototypes that are capable of functioning as close to the finished product as possible.

High-Capacity Production

Sheet metal fabrication can be carried out at high capacity. If there is a business that requires fast production of sheet metal products in bulk, sheet metal fabrication is the way to go. The high-capacity production of sheet metal parts allows for faster distribution of finished parts into the wider market in a shorter space of time.

Durable Materials

Sheet metal products can be made from steel, aluminum, galvanized steel, cold-rolled steel, copper, or stainless steel. These metals are alloys exhibiting various properties that must be considered by manufacturers based on their specific needs. These factors include weldability, strength, tensile strength, ductility, machinability, strength-to-weight ratio, toughness, etc. Aluminum, for example, is the most ductile material of all these alloys since it is light in weight and easy to machine. However, for more durability and corrosion resistance, a better choice would be galvanized or stainless steel.

Modern Finish

Sheet metals have a modern and aesthetically-pleasing design, even without any sort of metal coating, and finishing processes only enhance the appearance of these products. There are different types of finishing processes that can be used including polishing, sandblasting, burnishing, or grinding. These modern finishing processes can bring more value to nearly anything made from these materials.

Choosing the Proper Sheet Metal Fabrication Company

To make sure you have the most beneficial outcome when selecting a sheet metal fabrication company, it is important to compare at least 4 to 5 manufacturers using our sheet metal fabrication directory. Each sheet metal fabrication company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the company for more information or request a quote. Review each sheet metal fabrication company using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple sheet metal fabrication companies with the same quote.

Broaching

Broaching CNC Machining

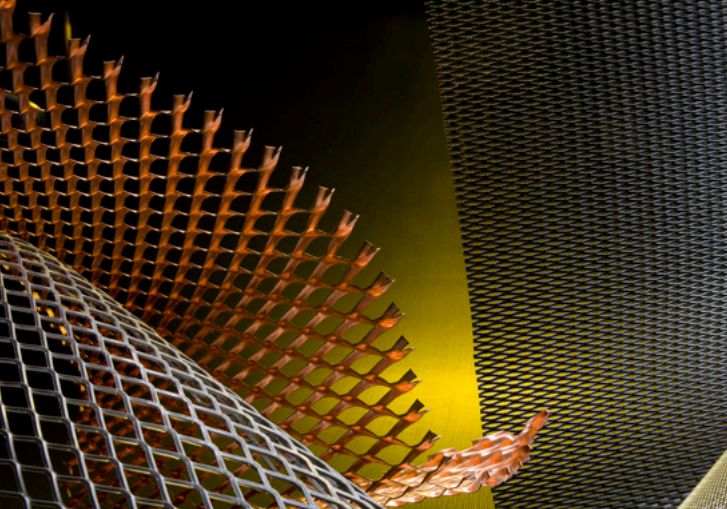

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

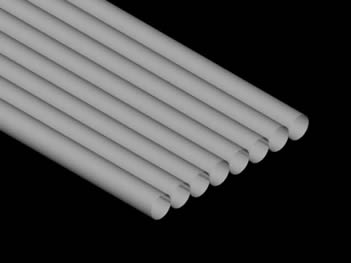

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services