Sheet metal fabrication is a versatile process that plays a crucial role in various industries. It involves shaping and manipulating thin sheets of metal to create a wide range of products. Sheet metal fabricators are skilled professionals who specialize in transforming raw metal into functional components, utilizing a combination of tools and techniques. Read More…

Maysteel provides complex sheet metal fabrication with a focus on design for manufacturing. Founded in 1936, we combine our extensive engineering experience and market knowledge with an expanding supply chain footprint, allowing us to fabricate products that others can’t. We design, engineer and manufacture custom OEM sheet metal enclosures, kiosks, cabinets and racks. We have locations in the...

At Continental Industries, we specialize in delivering top-tier sheet metal fabrication solutions, catering to a diverse range of industries with our commitment to excellence and precision. With decades of collective experience and a robust infrastructure, we have established ourselves as a trusted leader in the sheet metal fabrication sector. Our product portfolio includes a wide array of sheet...

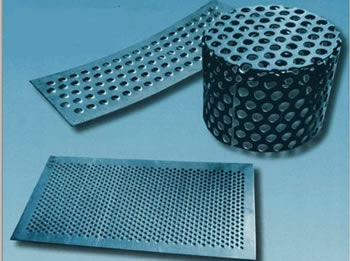

Accurate Metal Fabricating has been providing metal fabrication to OEM's and job shops for over 80 years. We fabricate, engineer, and perforate to the most precise specifications for the most demanding companies. We offer a full range of metal customization and fabrication capabilities that bring your design to reality. Our abilities range from forming and laser-cutting to powder coating and...

At Precision Metal Works LLC, we pride ourselves on being a leading provider of top-quality sheet metal fabrication solutions, dedicated to delivering precision-engineered products and exceptional services to our valued clients across various industries. With years of collective experience and a passion for innovation, we have established ourselves as a trusted partner in the field of sheet metal ...

Since 1981, American Industrial has been on the cutting edge of all things sheet metal. This has helped us achieve our spot as a leader of the industry.

More Sheet Metal Fabricator Companies

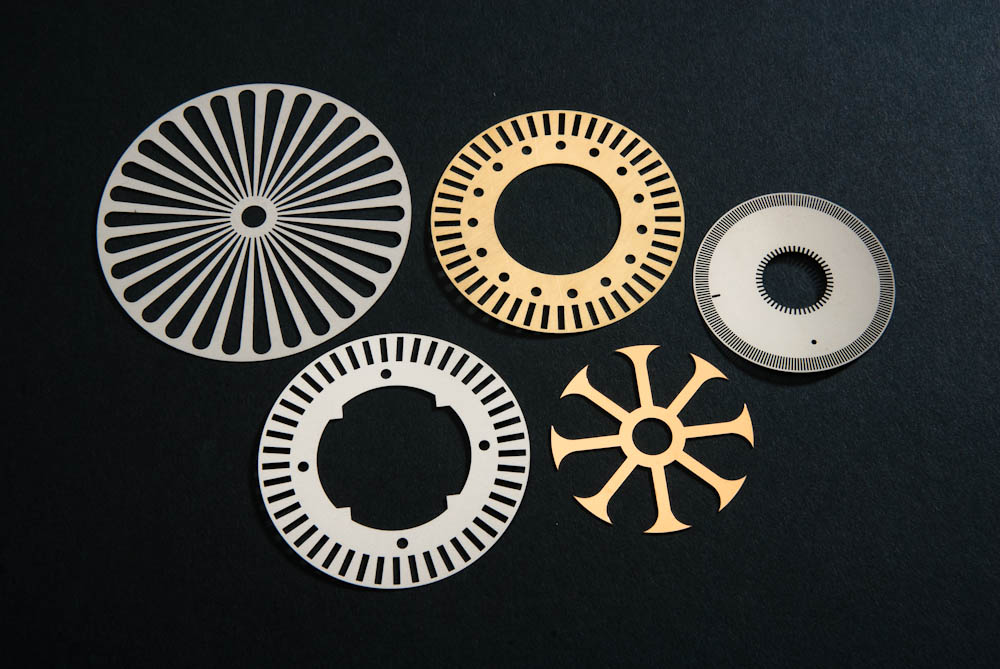

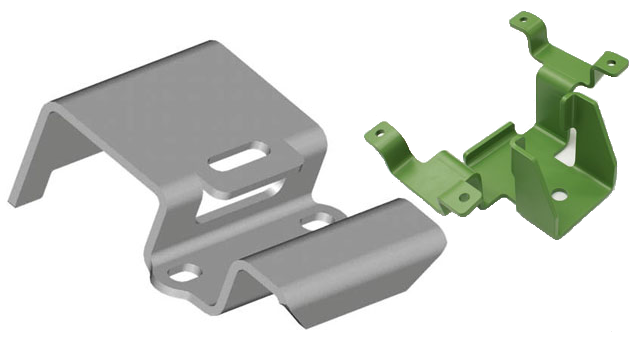

Items Requiring the Services of Sheet Metal Fabricators

Sheet metal fabricators are involved in the production of numerous items across various industries. Some notable examples include HVAC systems and ductwork, automotive components, aerospace parts, kitchen appliances, and electronic enclosures. These products require precision and expertise in sheet metal fabrication to ensure optimal performance, durability, and aesthetic appeal.

Tools Used by Sheet Metal Fabricators

Sheet metal fabricators rely on a range of specialized tools to shape and manipulate metal sheets. These tools include shears and snips for cutting, press brakes for bending, punches and dies for creating holes and shapes, welding equipment for joining metal pieces, and CNC machines for precise cutting and shaping. Each tool serves a specific purpose and is crucial in achieving the desired outcomes in sheet metal fabrication.

Education Required for Sheet Metal Fabricators

Becoming a sheet metal fabricator requires a combination of practical skills and theoretical knowledge. While formal education is not always mandatory, vocational training programs and certifications are highly recommended to acquire the necessary expertise. These programs provide comprehensive instruction in blueprint reading, welding techniques, computer-aided design (CAD), and the operation of sheet metal fabrication tools and equipment.

Considerations Regarding Sheet Metal Fabricators

When considering the employment or use of sheet metal fabricators, there are some potential negative considerations to keep in mind. One such consideration is the need for clear communication and collaboration between the fabricator and the hiring company. Misunderstandings or lack of clarity regarding design specifications, project timelines, or budget constraints can lead to delays, rework, or cost overruns. Additionally, relying on external fabricators may introduce logistical challenges, particularly when it comes to coordination and delivery schedules. Another consideration is the potential risk of intellectual property protection, especially when working on proprietary designs or confidential projects. It becomes crucial to establish appropriate confidentiality and non-disclosure agreements to safeguard sensitive information. Lastly, fluctuations in the availability of skilled sheet metal fabricators in the job market can pose challenges, especially during peak demand periods, potentially impacting project timelines. Therefore, careful planning, effective communication, and contractual agreements are essential to mitigate these negative considerations and ensure a successful collaboration with sheet metal fabricators.

Benefits Provided by Sheet Metal Fabricators

Despite these considerations, sheet metal fabricators offer numerous benefits. One of the key advantages is customization. Sheet metal fabricators can tailor their equipment and abilities to specific design requirements, allowing for unique and precise shapes, sizes, and finishes. This flexibility enables businesses to achieve their desired aesthetics and functionality while meeting specific project needs. Another significant benefit is cost-effectiveness. Sheet metal fabrication processes used by sheet metal fabricators are often more efficient, reducing material waste and optimizing production timelines. This leads to cost savings for businesses, making sheet metal fabrication a cost-effective solution compared to other manufacturing methods. Durability and strength are also inherent qualities of components created by sheet metal fabricators. These fabricated products exhibit excellent structural integrity, making them suitable for applications that require robustness and long-lasting performance. Moreover, sheet metal fabricators are known for their quick turnaround times. With their expertise and efficient production processes, they can deliver projects promptly, contributing to accelerated production schedules and reduced downtime. Furthermore, sheet metal fabricators offer expertise in material selection, production optimization, and value engineering and, as a result, they can provide insights and recommendations to enhance product design, improve manufacturing efficiency, and ultimately drive overall cost savings. These additional benefits highlight the value that sheet metal fabricators bring to businesses, making them an invaluable resource in achieving high-quality, customized, and cost-effective metal products.

Applications of Sheet Metal Fabricators

Sheet metal fabricators demonstrate their versatility and expertise in a wide range of industries. In the construction and architecture sector, for example, they contribute to structural components, decorative elements, and customized metalwork, elevating the aesthetic appeal of buildings. In the manufacturing and engineering industries, meanwhile, sheet metal fabricators manufacture machinery, equipment, and prototypes with precision and durability. The automotive and transportation sectors also rely on their skills to produce vehicle components and body panels, ensuring both safety and performance. In the aerospace and aviation industries, moreover, sheet metal fabricators are crucial in manufacturing aircraft parts and assemblies, adhering to stringent quality and safety standards. Furthermore, sheet metal fabricators play a vital role in the energy and renewable resources sectors by producing specialized equipment and enclosures for power generation and distribution. Additionally, they bring their expertise to the realm of HVAC systems, crafting ductwork and ventilation systems that facilitate efficient airflow and temperature control. In the realm of kitchen appliances, sheet metal fabricators contribute to the production of components like range hoods, oven backsplashes, and venting systems. Finally, in the electronics industry, they excel in constructing robust and tailored enclosures to protect sensitive electronic components from environmental factors. These applications across a range of industries demonstrate the essential role of sheet metal fabricators in creating high-quality, customized, and durable products to meet the unique needs of each sector.

Hiring of Sheet Metal Fabricators

Sheet metal fabricators can be hired directly by companies, particularly those with consistent sheet metal fabrication needs. They can also be engaged as a service, offering their expertise to businesses on a project basis. The choice between direct employment and outsourcing depends on factors such as the frequency of sheet metal fabrication requirements, the complexity of projects, and available resources.

Choosing a Proper Sheet Metal Fabricator

To ensure you have the most positive outcome when selecting a sheet metal fabricator it is important to compare many businesses using our directory of sheet metal fabrication companies. Each sheet metal fabrication company has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the fabricator for more information or to request a quote. Review each sheet metal fabricator business website using our proprietary website previewer to quickly learn what each sheet metal fabricator specializes in. Then, use our simple RFQ form to contact multiple sheet metal fabricators with the same form.

Broaching

Broaching CNC Machining

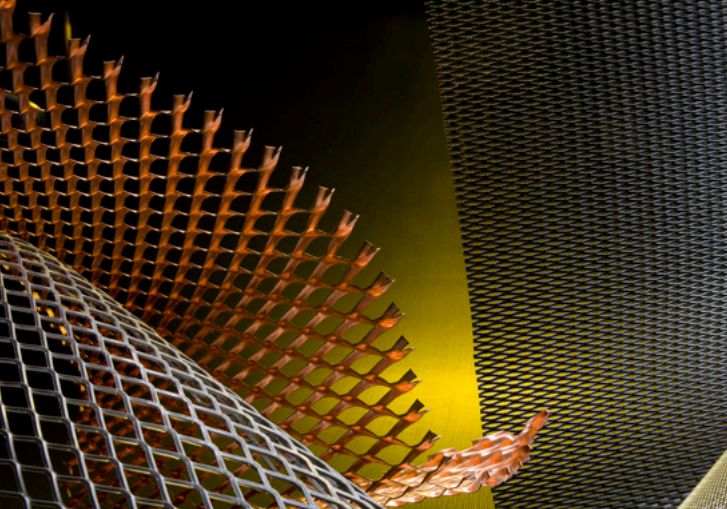

CNC Machining Expanded Metals

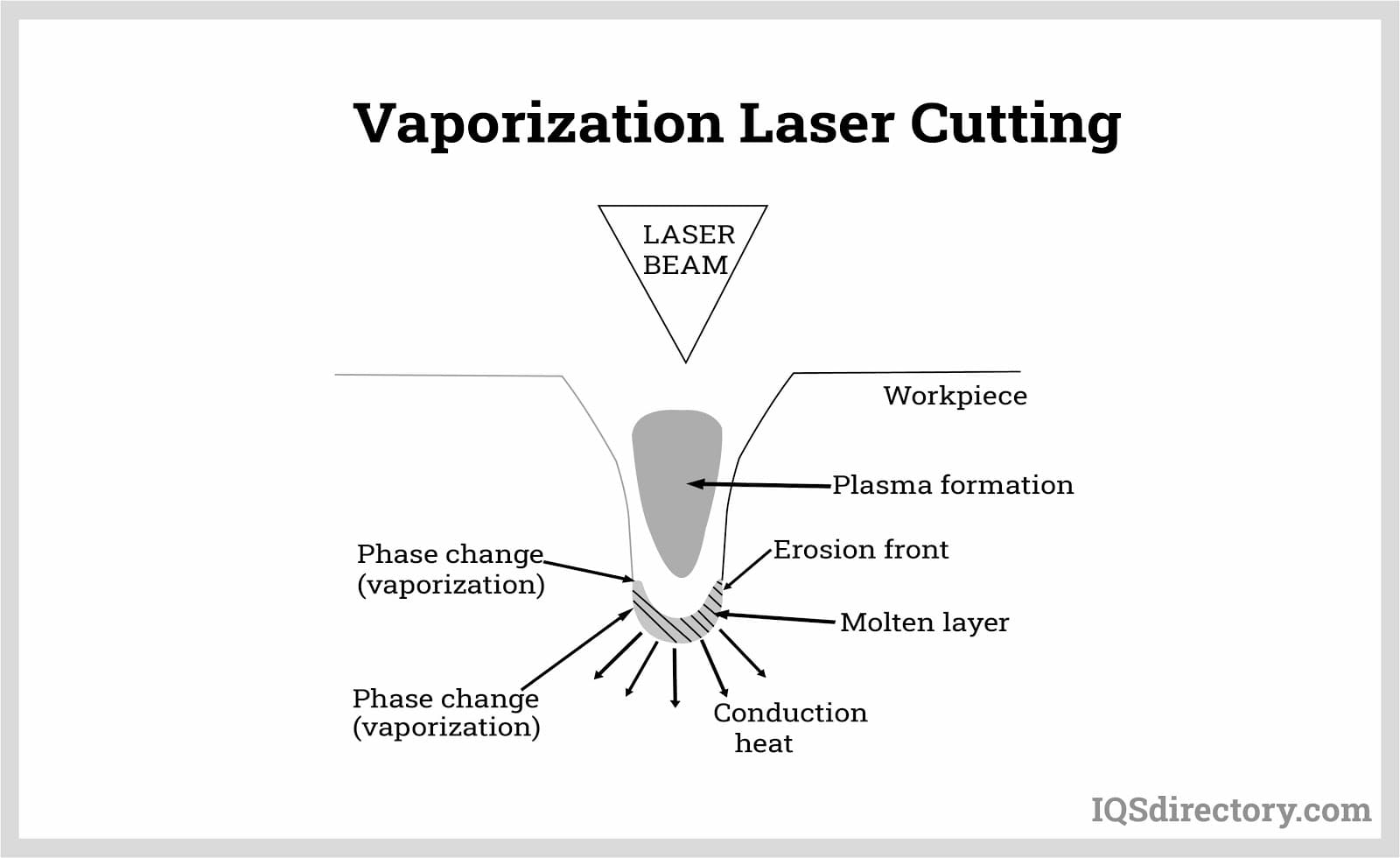

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

Metal Fabrication Perforated Metals

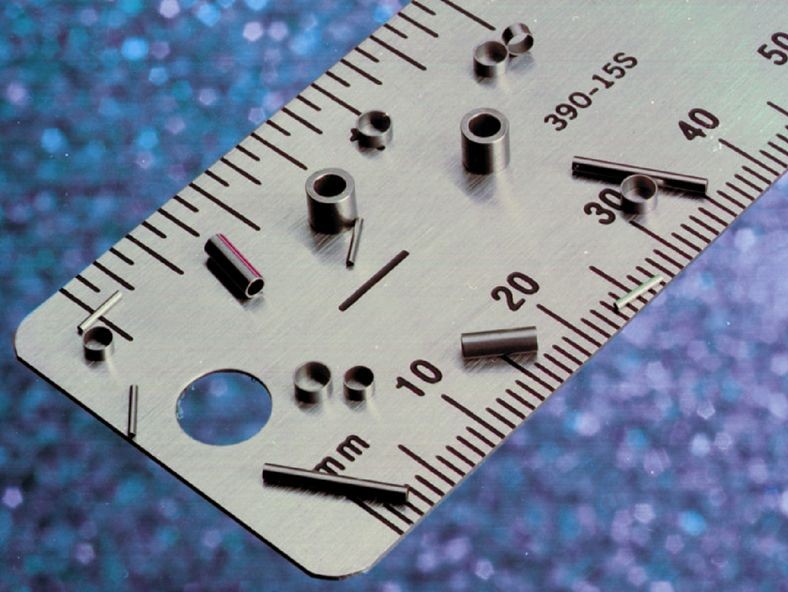

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services