Sheet metal parts are products that are formed from thin flat pieces of metal, mostly by an industrial process. These sheet metal parts are single items that can be formed for use as-is, or they can be joined together in many configurations to create a larger item like a weldment. From there, weldments and additional sheet metal parts can be combined by joining them together to create metal assemblies in a variety of shapes and sizes. Read More…

Maysteel provides complex sheet metal fabrication with a focus on design for manufacturing. Founded in 1936, we combine our extensive engineering experience and market knowledge with an expanding supply chain footprint, allowing us to fabricate products that others can’t. We design, engineer and manufacture custom OEM sheet metal enclosures, kiosks, cabinets and racks. We have locations in the...

At Continental Industries, we specialize in delivering top-tier sheet metal fabrication solutions, catering to a diverse range of industries with our commitment to excellence and precision. With decades of collective experience and a robust infrastructure, we have established ourselves as a trusted leader in the sheet metal fabrication sector. Our product portfolio includes a wide array of sheet...

Accurate Metal Fabricating has been providing metal fabrication to OEM's and job shops for over 80 years. We fabricate, engineer, and perforate to the most precise specifications for the most demanding companies. We offer a full range of metal customization and fabrication capabilities that bring your design to reality. Our abilities range from forming and laser-cutting to powder coating and...

At Precision Metal Works LLC, we pride ourselves on being a leading provider of top-quality sheet metal fabrication solutions, dedicated to delivering precision-engineered products and exceptional services to our valued clients across various industries. With years of collective experience and a passion for innovation, we have established ourselves as a trusted partner in the field of sheet metal ...

Since 1981, American Industrial has been on the cutting edge of all things sheet metal. This has helped us achieve our spot as a leader of the industry.

More Sheet Metal Part Companies

Weldments

These are sheet metal parts that have been joined together through welding. Weldments can be composed of several sheet metal parts and their sizes can vary greatly according to their intended use. When these weldments are joined together, usually with additional parts such as panels or brackets, they are known as sheet metal parts assemblies.

Types of Sheet Metal Parts

The types of sheet metal parts include:

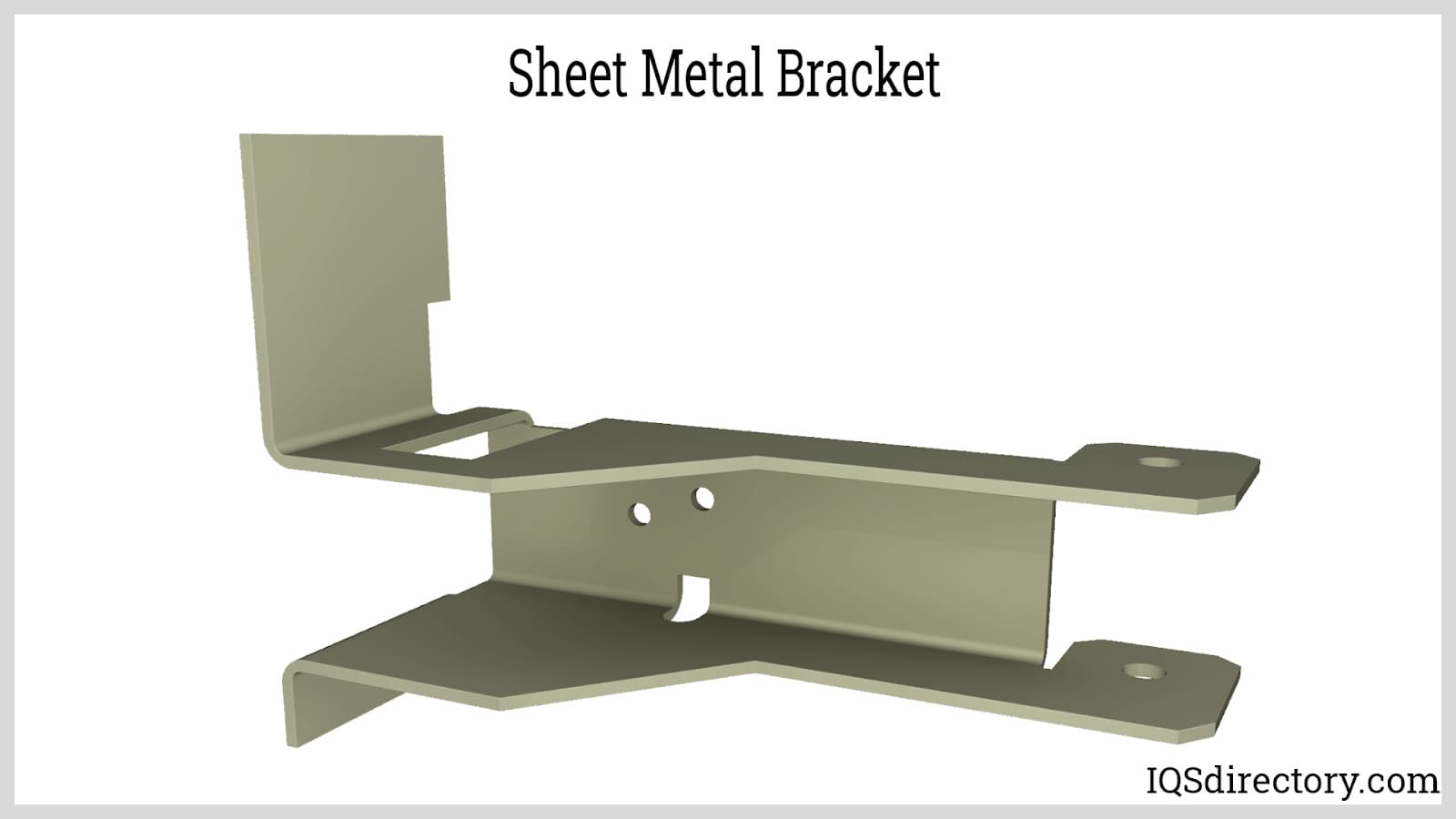

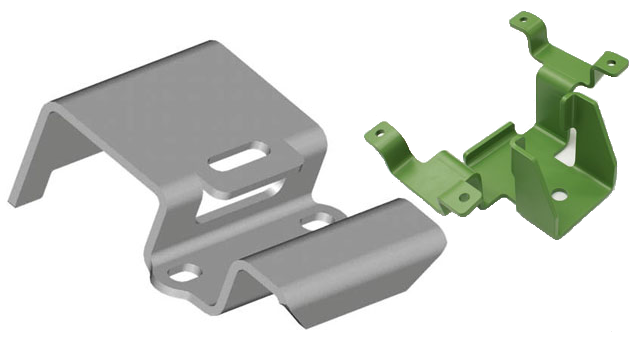

Sheet Metal Brackets

These are an extremely useful type of sheet metal parts. Sheet metal brackets can be formed or fabricated into almost any size depending on the requirements of the project. There are smaller metal brackets that are used for products like enclosure shelves. On the other hand, larger sheet metal brackets are used in structural steel projects. The metal brackets come in many different shapes as well and their shape depends on their specific purpose.

There are Z-brackets, for example, that are generally utilized in the mounting of offset parallel surfaces within a metal enclosure. On the other hand, gusset brackets often form a triangular shape and are meant for supplying additional rigidity and strength within an assembly or weldment. L brackets are utilized when there is a necessity for mounting a vertical component to a horizontal surface. They are helpful when there is a need to mount shelves within an enclosure.

Metal Hinges

These sheet metal parts allow for movement between two parts of a finished product or metal assembly by allowing the rotation of the two surfaces or parts around a fixed point. The most common type of sheet metal hinges allows for the opening and closing of a door or lid. Many examples of these parts are found in boxes and cabinets.

Industrial Sheet Metal Supports

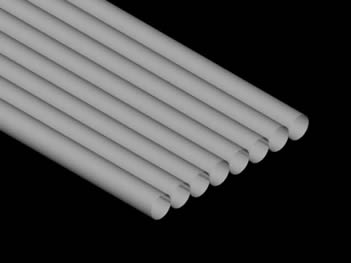

Sheet metal supports are used in many applications, but these types are utilized in the construction industry. Sheet metal parts that are used in the construction industry include poles, beams, pipes, tubes, and certain types of brackets.

Commercial Sheet Metal Frames

These are a type of assembly or weldment. They are found in many different sizes and types depending on the application requirement. They can be formed from structural steel for construction projects. However, smaller sheet metal frames such as those for windows, doorways, and shelving are all part of the metal frame category as well. These can be constructed from metals like aluminum or stainless steel.

Applications of Sheet Metal Parts

Sheet metal parts are used in many industries including the following:

- They are utilized for automobile and truck bodies.

- Sheet metal parts create airplane fuselages and wings.

- Major appliances are constructed from sheet metal parts.

- Tinplate may still be used for cans.

- In architectural settings, they often serve as roofing for buildings.

- Sheet metal parts made from iron, as well as other materials that exhibit high magnetic permeability (also called laminated steel cores), have their applications in electric machines and transformers.

- Sheet metal parts are used for decorative purposes including in horse tack.

- Sheet metal parts are used in the construction industry

Benefits of Sheet Metal Parts

The benefits of sheet metal parts include:

Strength and Durability

Since sheet metal exhibits high strength and durability, sheet metal parts are capable of withstanding heat and greater pressure than those made from plastic. Furthermore, stainless steel, aluminum, or surface-treated steel have high resistance to corrosion, pressure, wear, and tear.

Malleability

On top of durability, sheet metal is also malleable. With the proper equipment, sheet metal can be bent into many shapes while still retaining its structural integrity and strength. Sheet metal parts can be stretched or compressed without cracking or breaking. Very specific shapes can be obtained when sheet metal is cast or molded.

Replaceability

Since they are typically made to standard sizes, sheet metal parts are easily replaceable. When many metal parts are used for making an assembly, instead of constructing the entire part out of one material, the individual components can be replaced without having to replace the entire assembly. This is one of the biggest advantages of using sheet metal parts over other materials. Replacing individual parts saves money over having to (sometimes repeatedly) replace entire assemblies.

Sustainability

Sheet metal parts are sustainable. Metal is a natural resource that is both economically and environmentally strategic. When specific sheet metal parts are no longer needed, they can be recycled indefinitely and turned into other parts.

Cost Effectiveness

Sheet metal parts are a more economical choice since tooling costs for plastics can be very high. Most companies utilize sheet metal parts instead of cast or molded parts due to the overall reduction in material waste and costs.

Choosing the Right Sheet Metal Parts Manufacturer

To make sure you have the most productive outcome when purchasing sheet metal parts from a sheet metal parts manufacturer, it is important to compare at least 4 to 5 companies using our list of sheet metal parts manufacturers. Each sheet metal parts company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each sheet metal parts company website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple sheet metal parts companies with the same quote.

Broaching

Broaching CNC Machining

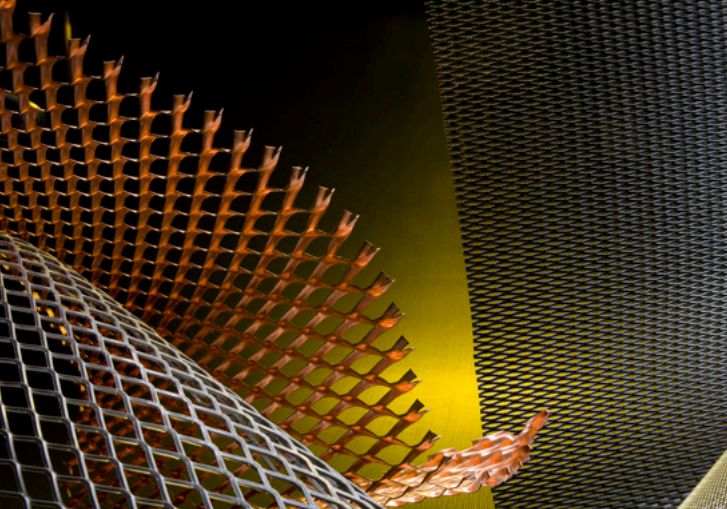

CNC Machining Expanded Metals

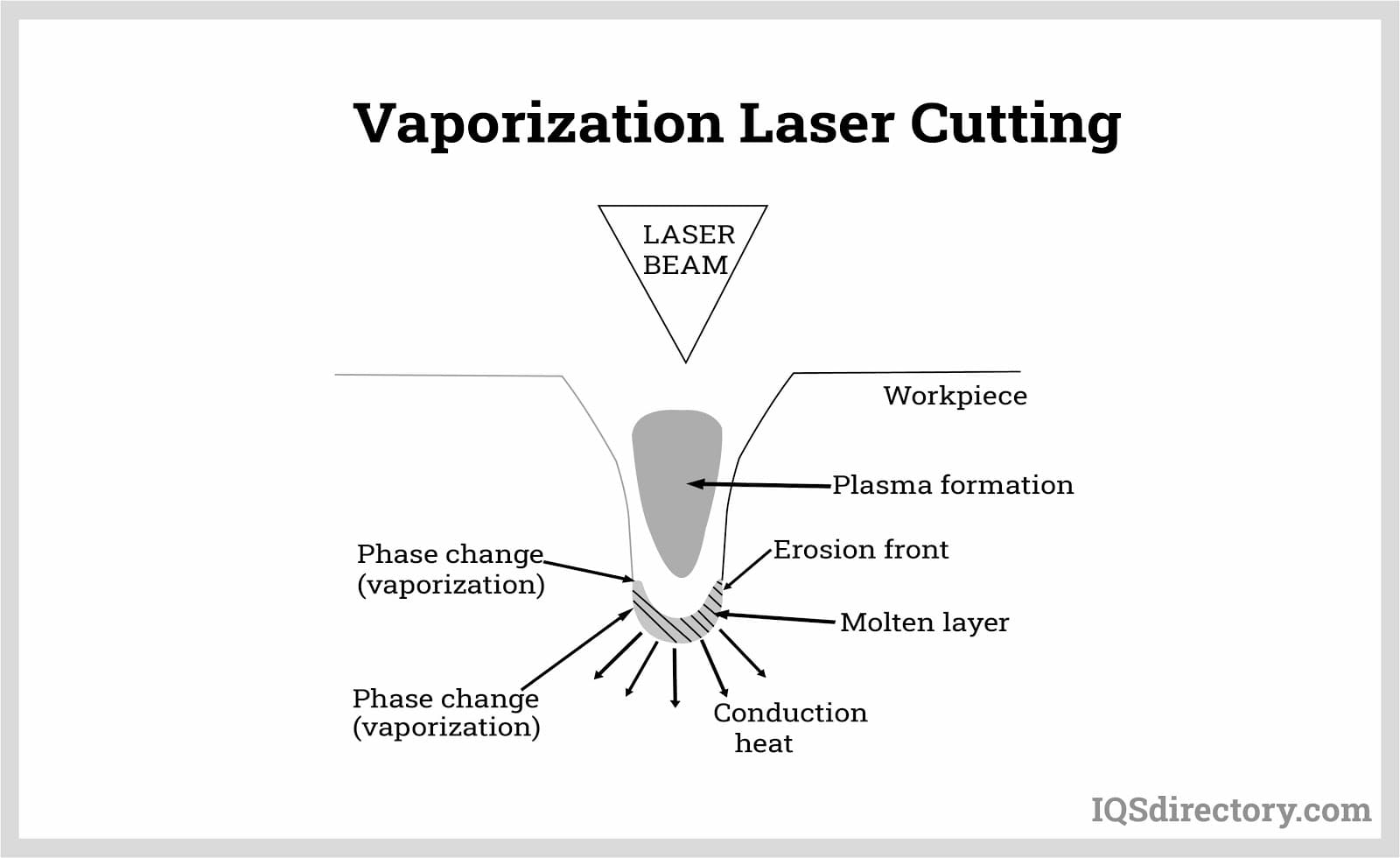

Expanded Metals Laser Cutting

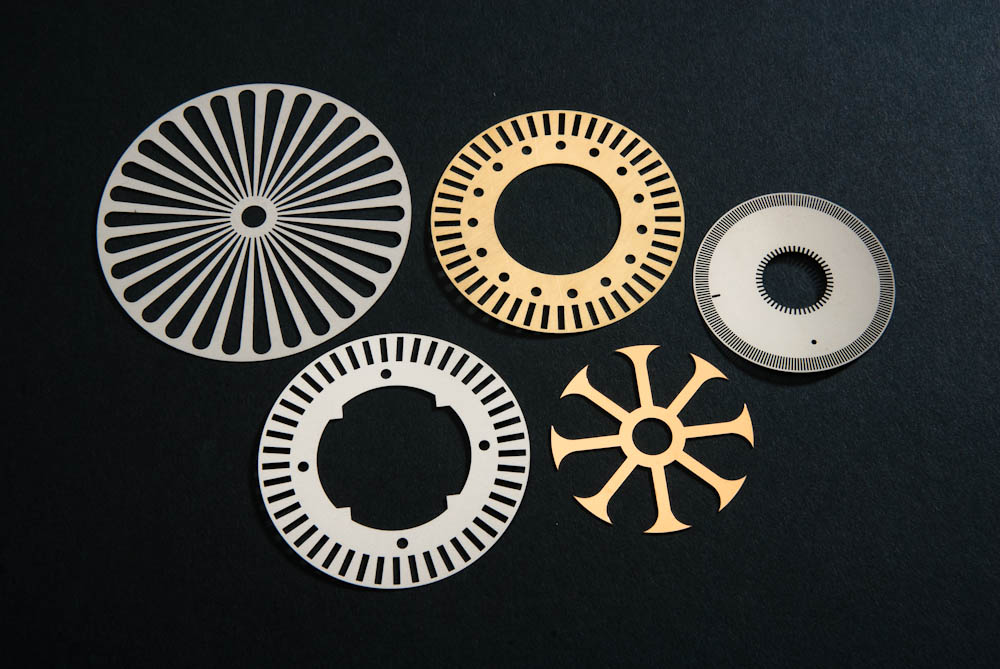

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

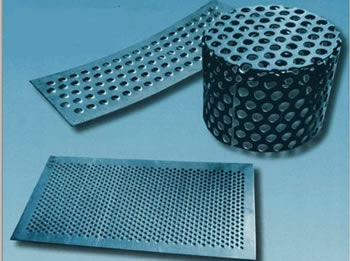

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

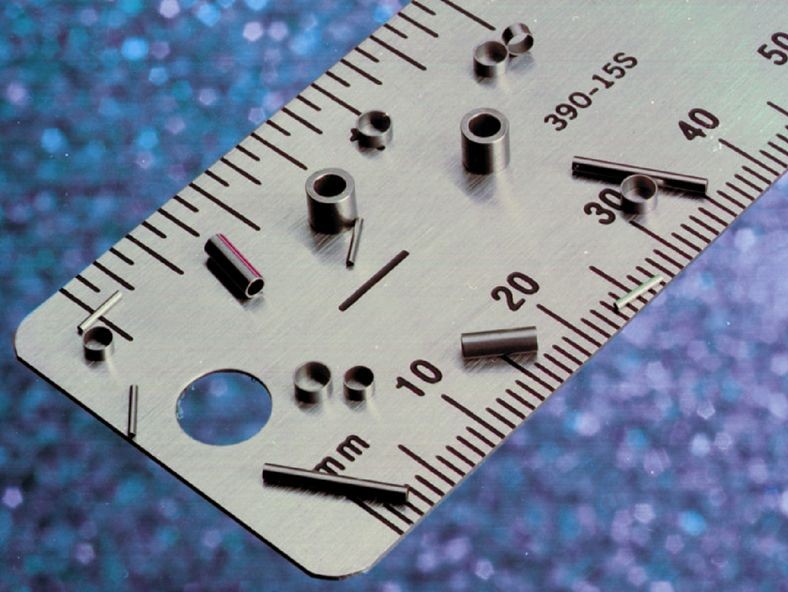

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services